Associate Professor

| HAKOYAMA Tomoyuki |

|

| Title |

|

|---|

| Department |

| Department of Mechanical Engineering |

|

|---|

| Course |

| Mechanical Engineering Course |

|

|---|

Research fields

For the weight reduction of transportation vehicles, the use of the light weight material such as high strength steel or aluminum alloy is increasing. However these materials have low formability. Therefore the role of the numerical calculation method (e.g. finite element analysis) become more important. The predictive accuracy of the elasto-plasticity analysis is domminated by the accuracy of the material model.

Current research topics are as follows:

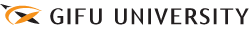

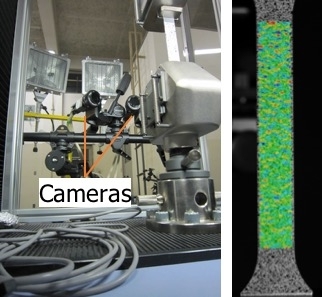

1. Development of a material model identification method using multi-axial material test

Easy and accurate identification method using the digital image correlation and the inverse analysis is being investigated.

2. Development of material model identification method using crystal plasticity analysis

Real-test-less material model identification using the macroscopic deformation behavior calculated by the virtual tensile test with crystal plasticity is being investigated.

3. Crystal texture measurement and application using neutron beam

Neutron beam is the useful tool for the non-destructive measurement because the penetration of the neutron beam is larger than the electron beam and X-ray. The optimization of the texture measurement system using neutron beam and its application is being investigated.

|

|

| Fig.1 Comparison of the sheet forming and the finite element analysis |

Fig.2 Measurement of the deformation behavior using the digital image correlation |

Research Keywords

| Elastoplasticity Theory, Metal Forimig, Computational Engineering, Quantum Beam Measurement |

Details page