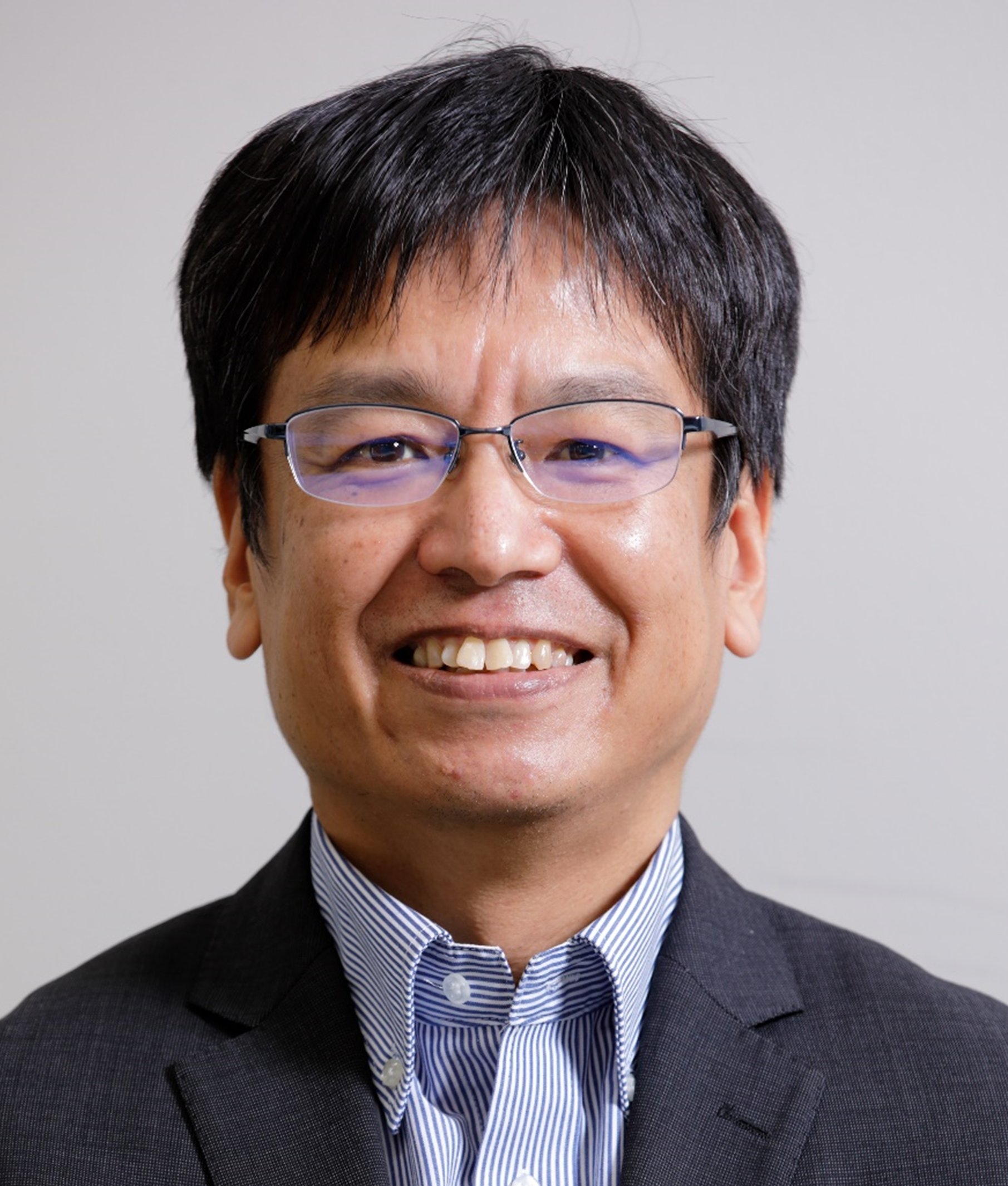

Professor

|

UNEDA Michio |

|

| Title | Professor |

|---|---|

| Department | Department of Mechanical Engineering |

| Course |

Mechanical Engineering Course |

Research fields

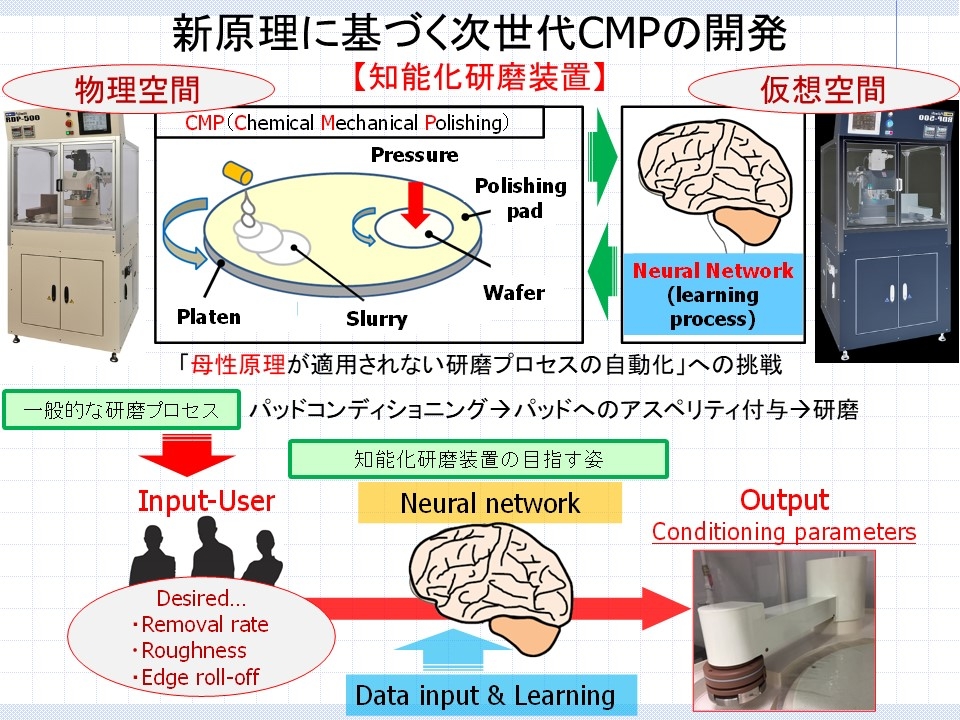

The Precision Engineering Laboratory conducts various research projects on the ultra-precision process called CMP: Chemical Mechanical Polishing. Examples of research projects include

- Proposal and practical application of a new visualization method for the CMP process and development of highly functional consumables,

- Developing the next generation of CMP based on new principles,

- Understanding the science and mechanism of CMP.

In addition, the Precision Engineering Laboratory is developing the following as new manufacturing processes

- Development of next-generation robotic manufacturing systems for molds and automotive bodies,

- Development of cyber-physical system (CPS) through process visualization and AI application.

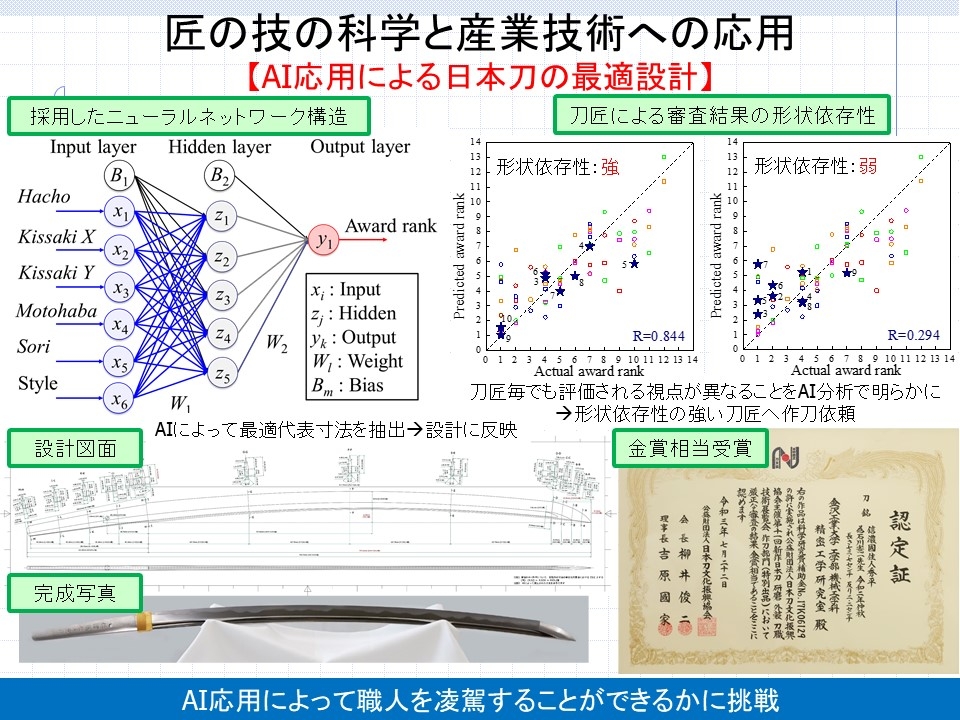

In addition, the Precision Engineering Laboratory is also challenging the science of craftsmanship as follows

- Visualization of craftsmanship sensitivity,

- Optimal design of Japanese swords through AI application,

- Standardizing cutlery science and developing innovative technology.

In particular, the Precision Engineering Laboratory will work on cutlery science by using the triangle model based on quality control, mechanization/automation, and new material development, and promote the exploration of beauty from the point of view of user needs.

The laboratory's motto is "If we don't have it, we will make it ourselves". Let's enjoy various manufacturing and cutting-edge research activities together.

|

|

|

Successful development of intelligent polisher through AI application |

Creating new solutions through the science of craftsmanship |

Research Keywords

Precision engineering, Ultra precision manufacturing process, AI application, Science of craftsmanship, Cutlery science